After the load test, we often need additional grouting into the gaps that created between the upper and lower part of piles to restore the load transfer.

Very small gaps are not necessary for additional grouting because they will conglutinate themselves after a long-time working.

Larger displacement during load test causes bigger gaps. Then additional grouting is needed. The different methods in fabrications of the jacks will lead to different flow spaces for drilling fluid to flow around jack location. Due to the different of the spaces, hence the concrete quality and geometry around these spaces are different. Furthermore, there are difficulty in post grouting after load test in these spaces and the performances of the grouted spaces also different.

Larger displacement during load test causes bigger gaps. Then additional grouting is needed. The different methods in fabrications of the jacks will lead to different flow spaces for drilling fluid to flow around jack location. Due to the different of the spaces, hence the concrete quality and geometry around these spaces are different. Furthermore, there are difficulty in post grouting after load test in these spaces and the performances of the grouted spaces also different.

Advantages of YJack for Additional Grouting

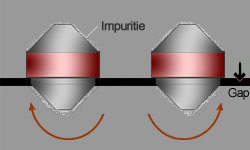

- Loading with YJack, the piles will precisely break apart on the designed horizontal plane.

That is helpful to determine the position of hole opening on grouting pipe.

- Loading displacement makes simple-shaped gap. The simple shape helps the slurry flowing to fill the gap better.

- If take out of top and bottom steel plates, sediments would flow through up more fluently; this avoids sediments blocking around the jacks.

That will meet the correct concrete constituents and expected concrete strength after additional grouting.

- Accurate break-apart position on the pile, simple-shaped gap and trace amount of impurities will simplify the additional grouting,

improve the grouting result and ensure the safety usage of the pile in the future.